The first step is for both parties to set metrics for success and agree on terms and conditions for the partnership. Vendor managed inventory works by building a strong communication system between the seller and the buyer.

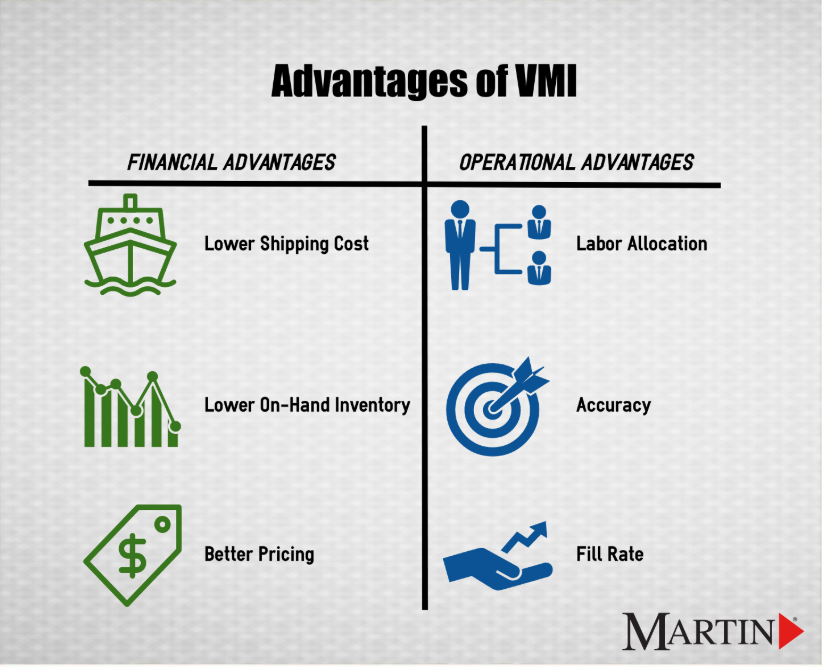

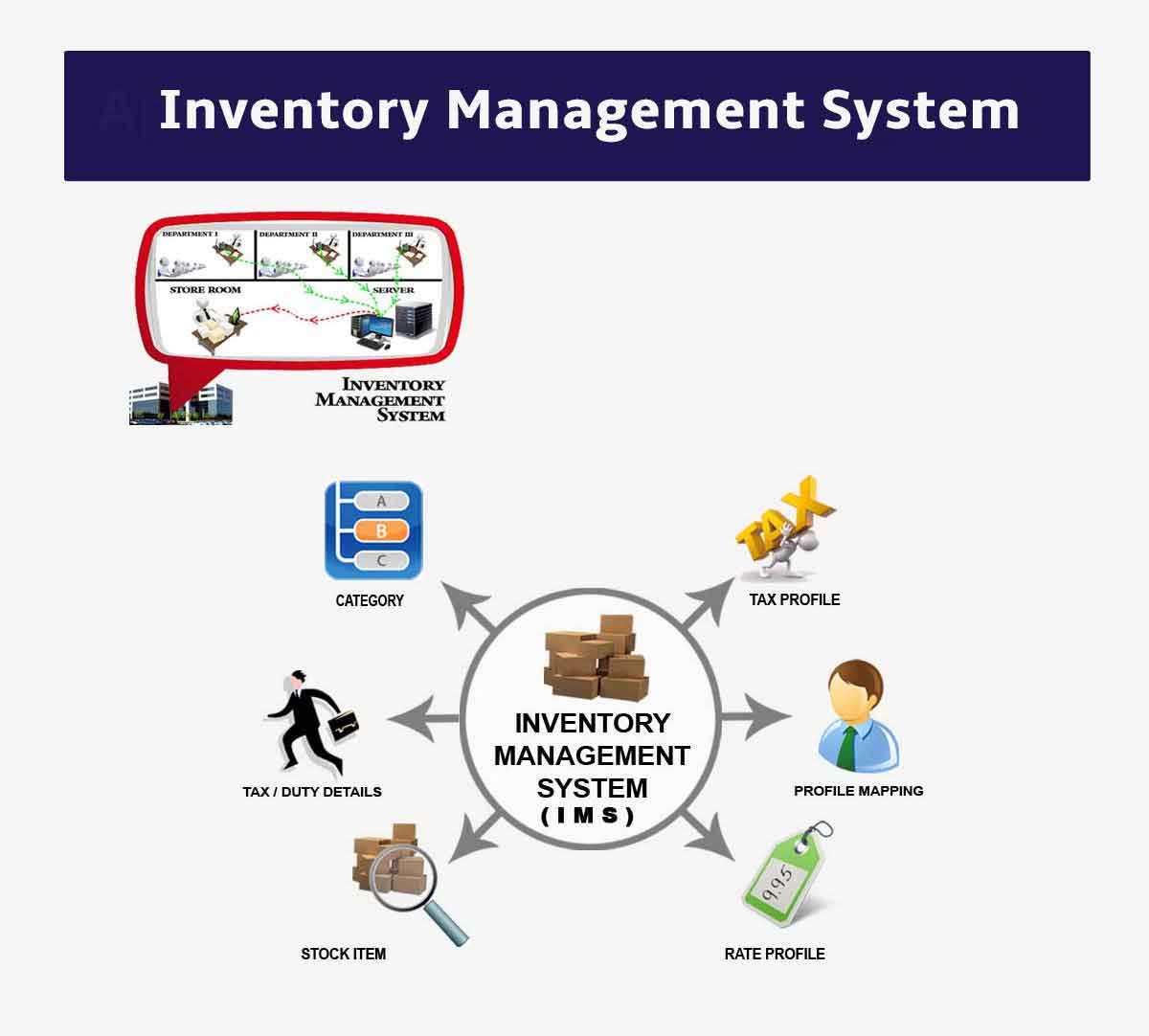

The goal of VMI is to reduce inventory-related costs for both parties. This means the retailer doesn’t need to actively order more inventory to stock its shelves because the vendor has access to inventory levels and determines when the business needs more stock. It’s an inventory management system that puts the seller (the vendor) in charge of inventory instead of the buyer (the retailer). Vendor managed inventory (VMI) is a partnership between a vendor and a retailer in which the vendor takes control of the retailer’s inventory.

Vendor management inventory software how to#

This post will discuss the benefits of vendor managed inventory and how to implement it successfully. Vendor managed inventory (VMI) solves these issues by putting the supplier, or vendor, in charge of inventory - even once it’s in the retailer’s warehouse.

Purchasing too much product can lead to overspending while ordering too little can lead to missed sales.

Inventory management often relies on retailers’ predictions of their needs, which may or may not be accurate. Vendor managed inventory - benefits, risks, and best practices

0 kommentar(er)

0 kommentar(er)